HMK-1600 Auto bag filling packaging machine

|

Function and Characteristics |

|

1、Easy to operate,adopt advanced SCPU from US ROCKWELL, mate with touch screen and electric control system. 2、Safety device: Machine stop at abnormal air pressure, heater disconnection alarm。 3、The width of the bags could be adjusted by servo motor. This machine used the servo film transport technology and pouch conveying unit for servo system technology, The HMI modification parameter could be adjusted bag size, easily operate, and save time. 4、It machines with the glass safety door. The machine will stop working when you open the door. So that it could protect the safety of operators. At the same time, it could prevent dust. 5、Product or packaging bag contact parts adopt stainless steel or other materials which accord with the food hygienic requirements, guarantee hygiene and security of the food. 6、With different feeders changed to pack solid, liquid, thick liquid ,powder and so on. 7、The packaging bag suits in extensive range, suit for multi-layer compound, monolayer PE , PP and so on film. |

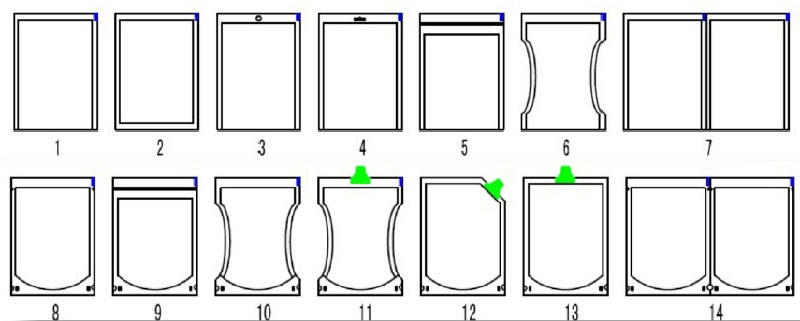

Sample:

|

Machine technical DATA: |

||

|

HMK 1600 |

||

|

Machine operation |

HFFS |

Horizontal form fill and seal |

|

Technology concept |

Pouch origin |

Form the reel |

|

Pouch transport system |

intermittent |

|

|

Construction |

Machine frame |

Stainless steel SUS304 |

|

Except internal mechanisms |

Stainless steel SUS304,and Aluminum alloy |

|

|

Parts in contact with product |

Stainless steel SUS316L |

|

|

Reel |

Reel diameter |

500mm |

|

Reel Width |

62mm |

|

|

Reel core |

76mm |

|

|

Filling stations |

|

2 (with 2 heads) |

|

Machine dimensions |

Length×width×height |

5230×1000×2000mm |

|

Machine weight |

|

2000Kg |

|

Pouch dimensions |

Length×width×height |

Minimum: 70mm×110mm Maximum: 160mm×250mm |

|

Packaging speed |

|

FOR SPECIAL SHAPE 20-30 BAGS PER MIN,FOR NORMAL DOY PACKER WITHOUT SPOUT 40-50 BAGS PERM IN |

|

Pouch volume |

simplex |

Maximum:250c.c |

|

Consumption |

Electrical |

6.0kw |

|

Air consumption |

80L/min 0.6Mpa |

|

|

Electrical Data |

|

200-415V/50-60Hz/N+G(According to customer requirements customization) |

|

Noise level |

|

≤70dB |

|

Safety |

|

CE standards |

|

Jacket Heating Tank |

|

150 L |

|

Filler |

|

2 Piston Filler |